3.5% sulphur Calcined Coke

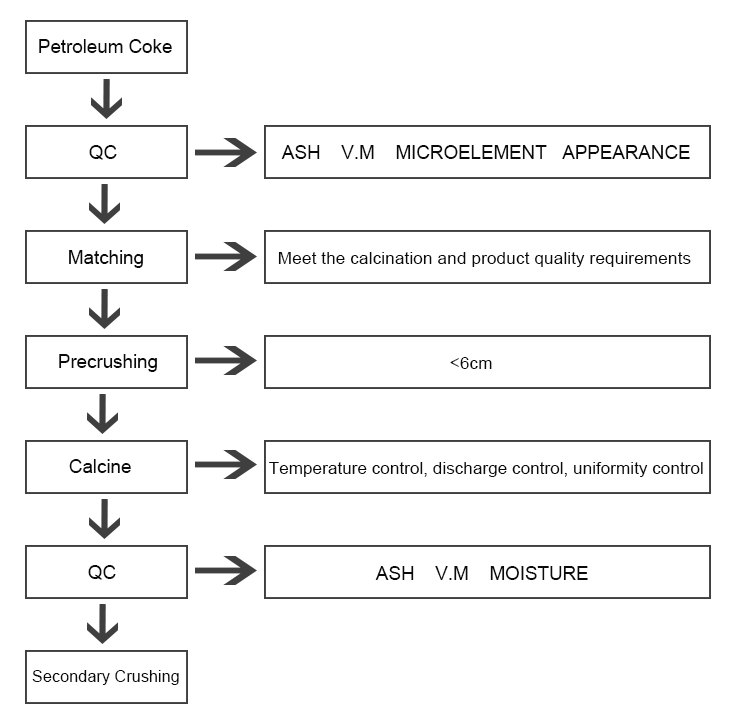

Calcined petroleum coke (CPC) is a high-quality carbon material derived from petroleum residue (also known as green coke). It is produced through the process of calcination, which involves heating green coke to high temperatures in order to remove impurities and volatile matter, resulting in a pure carbon product with a high carbon content. The production process of calcined petroleum coke typically involves the following steps:

Petroleum Coke Preparation: Raw petroleum coke is obtained from petroleum refineries as a byproduct of the distillation process. It is a solid carbon-rich material with a high calorific value.

Crushing and Grinding: The raw petroleum coke is typically crushed and ground into a fine powder. This is done to increase the surface area of the coke particles, which aids in the subsequent calcination process.

Blending: Depending on the desired properties of the final product, different grades and types of petroleum coke may be blended together. This is done to achieve the desired carbon content and other specifications.

Calcination: The powdered petroleum coke is then subjected to high temperatures in a calcination kiln or rotary kiln. The temperature typically ranges between 1200 to 1350 degrees Celsius (2200 to 2500 degrees Fahrenheit). The calcination process removes moisture, volatile matter, and other impurities from the coke, resulting in a highly carbonized material. The calcination process also improves the mechanical strength and electrical conductivity of the coke.

Cooling: After calcination, the hot calcined petroleum coke is cooled either by direct contact with water or by indirect cooling methods, such as air cooling. The cooling process stabilizes the coke and reduces its temperature to a suitable level for handling and storage.

Screening and Sizing: The cooled calcined coke is then screened to remove oversized particles and impurities. The coke is also typically sized to meet specific requirements, such as particle size distribution and bulk density.

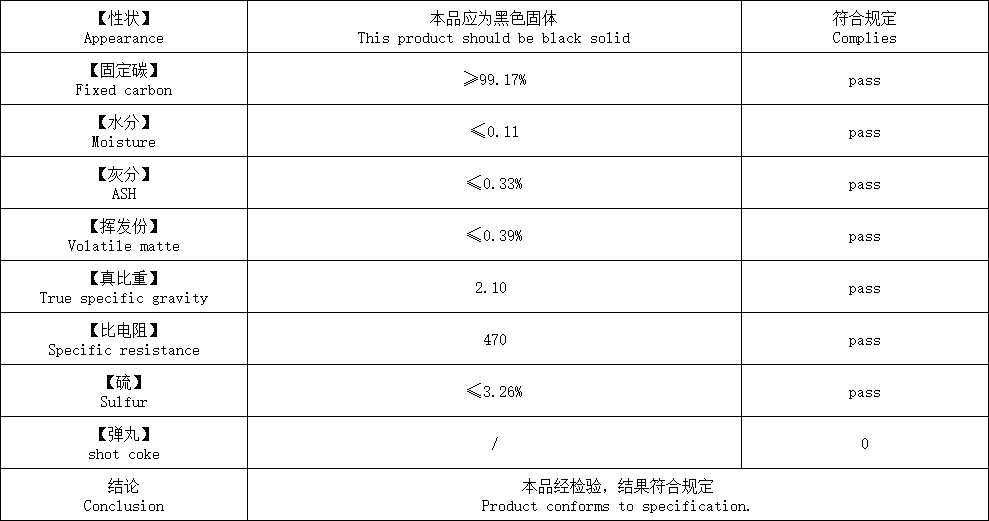

Quality Control: The final calcined petroleum coke product undergoes rigorous quality control testing to ensure it meets the desired specifications. This may include testing for carbon content, sulfur content, ash content, volatile matter, and other parameters.

Packaging and Storage: The calcined petroleum coke is packaged and stored in appropriate containers or bags to prevent moisture absorption and maintain its quality. It is commonly transported in bulk or packed in bags for shipment to various industries, such as aluminum smelters, steel producers, and carbon electrode manufacturers.

It is important to note that the exact production process may vary slightly between different manufacturers and refineries, but the general steps outlined above provide a good overview of the typical process for producing calcined petroleum coke.

The role of the negative material factory

Calcined petroleum coke (CPC) can also play a role in negative electrode materials, particularly in lithium-ion batteries. While graphite is the most commonly used material for the negative electrode (anode) in lithium-ion batteries, CPC can be used as a precursor or additive in certain electrode formulations. Here's a general overview of the role of CPC in negative electrode materials:

Carbon Source: The negative electrode in lithium-ion batteries requires a carbonaceous material that can efficiently intercalate lithium ions during charging and discharging cycles. Graphite is the most widely used carbon source due to its ability to reversibly store lithium ions. However, in some cases, CPC can be utilized as an alternative carbon source or as a precursor for the formation of carbon materials used in the negative electrode.

Electrochemical Performance: The electrochemical performance of the negative electrode material is crucial for the overall performance of the battery. CPC, when used as a carbon precursor, can be processed further to develop tailored carbon materials with desired properties. By adjusting the calcination conditions and other processing parameters, the carbon structure and surface properties of CPC-derived materials can be optimized to enhance lithium-ion intercalation/deintercalation, charge/discharge rate capability, and cycling stability.

Conductivity and Stability: Like in other applications, the high carbon content and excellent electrical conductivity of CPC contribute to the conductivity of the negative electrode material. Good electrical conductivity is essential to facilitate the transport of electrons during charging and discharging cycles. Additionally, CPC-derived carbon materials can offer improved stability and structural integrity, reducing the risk of electrode degradation or capacity loss over extended battery cycling.

Additive or Coating: In some cases, CPC can be used as an additive or coating material in negative electrode formulations. It may serve as a conductive additive to enhance the overall conductivity of the electrode or as a coating material to improve the adhesion and stability of the active electrode materials.

It's important to note that the specific use of CPC in negative electrode materials can vary depending on the battery chemistry, electrode design, and desired performance characteristics. The application of CPC in lithium-ion battery electrode materials is an active area of research and development, aiming to improve battery performance, energy density, and cycling stability.O

Specification

Line of production

Factory Show

Related Products

Submitted successfully

We will contact you as soon as possible

Related News

Submitted successfully

We will contact you as soon as possible