Calcined Petroleum Coke for Steel and Aluminium Plant

High Carbon Content: Calcined Petroleum Coke typically has a high carbon content ranging from 97% to 99.5%.

Low Impurity Levels: Calcined petroleum coke has significantly lower levels of sulfur, nitrogen, and other impurities Low impurity levels ranges from 0.05~4% .

High Density and Strength

Good Electrical Conductivity

Consistent Quality

Cost-Effective

What is the application of calcined petroleum coke

Calcined petroleum coke (CPC) is a critical raw material in the production of steel and aluminum. Calcined petroleum coke primarily used in the manufacturing process of anodes for aluminum smelting. The process involves calcining raw petroleum coke at high temperatures to remove impurities and moisture, resulting in a highly carbonized product known as calcined petroleum coke.Calcined petroleum coke mainly used in aluminum smelting,steel Industry,titanium dioxide production,graphite electrodes and other industrial applications,such as the production of carbon products, certain refractory materials, and other industrial processes requiring high carbon content.

Specifications of the calcined petroleum coke

| Analysis report | |||

| Sample name: | Calcined petroleum coke | Sample NO.: | ZC2023-010-10 |

| Sampling site: | screening workshop | Sampling date: | 2023/10/10 |

| Sulfur | GB/T214 | 0.5 | |

| V.M | SH/T0026 | 0.3 | |

| Ash | SH/T0029 | 0.48 | |

| Moisture | SH/T0032 | 0.2 | |

| Carbon | GB/T3521 | 98.5 | |

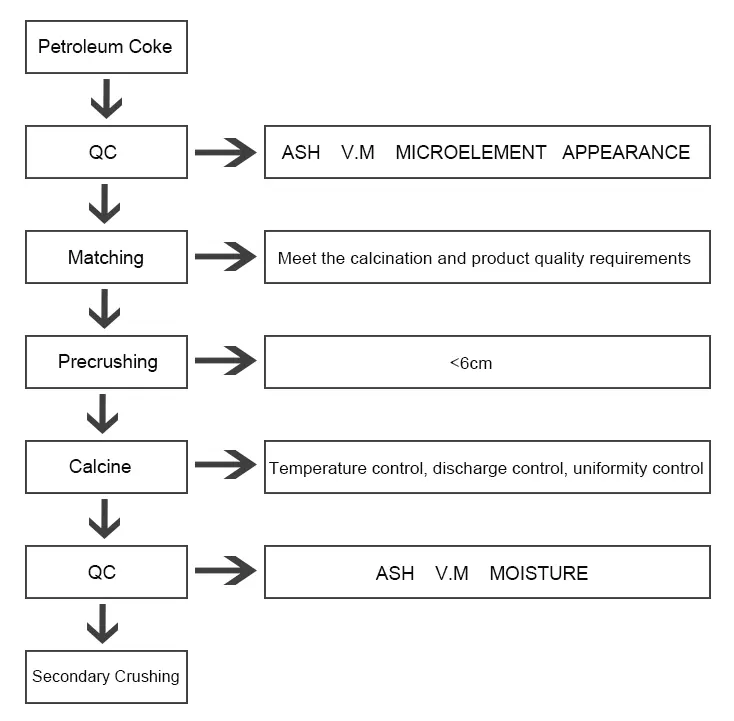

Manufacturing process

The manufacturing process of calcined petroleum coke (CPC) involves several stages, including raw material extraction, preparation, calcination, and quality control.