Calcined Petroleum Coke

Calcined Petroleum Coke (CPC) is commonly used as a key ingredient in the production of prebaked carbon anodes for aluminum smelting. Here are some advantages of using CPC in prebaked anodes:

High Carbon Content: Calcined Petroleum Coke typically has a high carbon content ranging from 97% to 99.5%. This high carbon content ensures that anodes made with CPC have sufficient carbon to effectively conduct electricity during the electrolysis process.

Low Impurity Levels: CPC undergoes a calcination process, which involves heating the raw petroleum coke at high temperatures to remove volatile matter and impurities. As a result, calcined coke has significantly lower levels of sulfur, nitrogen, and other impurities compared to raw petroleum coke. Low impurity levels are important because impurities can adversely affect anode performance and lead to increased electrical resistance, reduced efficiency, and anode degradation.

High Density and Strength: Calcined coke particles are typically larger and denser compared to raw coke particles. The increased density and strength of CPC particles contribute to the overall strength and mechanical stability of prebaked anodes. This is crucial during the anode baking process and subsequent handling and use in the electrolytic cell.

Good Electrical Conductivity: Calcined Petroleum Coke has excellent electrical conductivity, which is vital for efficient aluminum production. Anodes made with CPC provide a conductive path for the flow of electrical current through the electrolytic cell, facilitating the reduction of alumina into aluminum metal.

Consistent Quality: Calcined coke production involves precise control of the calcination process, resulting in a consistent quality product. This consistency ensures uniform anode performance, predictable electrical properties, and stable cell operation in aluminum smelters.

Cost-Effective: While the cost of CPC can vary depending on factors such as market conditions and availability, it is generally a cost-effective choice for the production of prebaked anodes. The superior properties of CPC contribute to the overall performance and durability of anodes, potentially reducing the frequency of anode replacements and downtime, thus optimizing operational costs.

Overall, the use of Calcined Petroleum Coke in prebaked anodes offers advantages such as high carbon content, low impurity levels, good electrical conductivity, high density and strength, consistent quality, and cost-effectiveness, making it a preferred choice in the aluminum smelting industry.

Advantage to using Calcined Petroleum Coke in prebaked anode

Calcined coke, also known as petroleum coke, offers several advantages in various industries. Here are some of the key advantages of calcined coke:

High carbon content: Calcined coke typically has a high carbon content, ranging from 98% to 99.5%. This high carbon content makes it an excellent source of carbon for processes that require carbon-rich materials, such as steel and aluminum production.

Low impurity levels: Calcined coke is produced through a process that removes volatile matter and impurities from raw petroleum coke. As a result, calcined coke has low levels of impurities, such as sulfur and metals, which can be beneficial for applications that require high purity and low contamination.

High heat content: Calcined coke has a high calorific value, meaning it releases a significant amount of heat energy when burned. This makes it an efficient fuel source for processes that require high temperatures, such as in industrial furnaces, power generation, and cement kilns.

Consistent quality: Calcined coke is produced under controlled conditions, ensuring consistent quality and properties. This predictability allows for better process control and product performance in various applications.

Cost-effectiveness: Calcined coke is often economically advantageous due to its competitive pricing compared to other carbon sources. Its availability, especially in regions with petroleum refining facilities, makes it a cost-effective choice for industries that require carbon-rich materials.

Environmental considerations: While calcined coke is a carbon-intensive material, it typically has lower sulfur and nitrogen content compared to alternative fuels like coal. This lower sulfur content can result in reduced emissions of sulfur dioxide (SO2) when used as a fuel, contributing to improved air quality and reduced environmental impact.

It's important to note that the advantages of calcined coke can vary depending on the specific industry, application, and regional factors. Additionally, environmental sustainability and compliance with regulations should be considered when evaluating the overall benefits and impacts of using calcined coke.

Specification

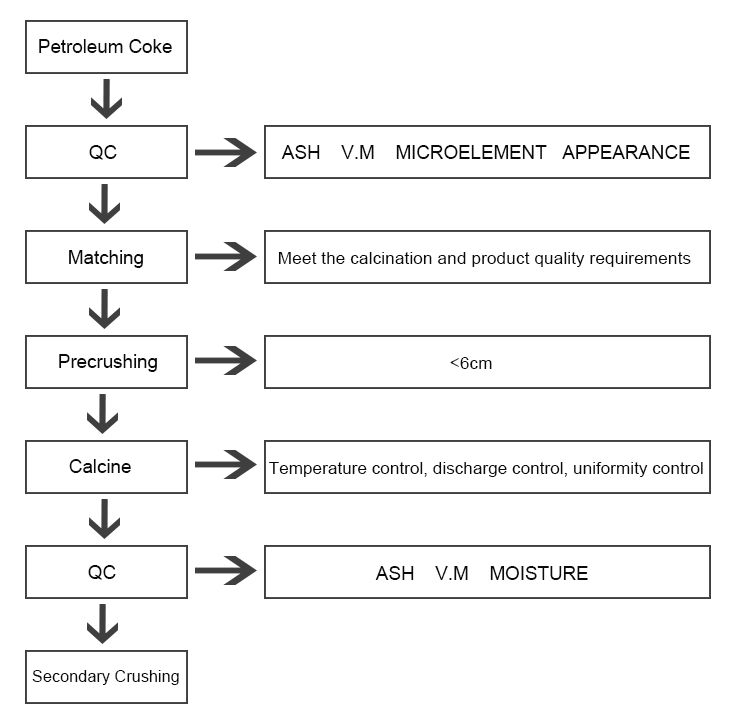

Production Line