Chinese Best Supplier For Calcined Coke

Calcined petroleum coke is a high-quality carbon material produced by heating green petroleum coke to remove volatile matter and impurities. It is widely used in various industries, including aluminum, steel, and graphite electrode manufacturing. The production process of calcined petroleum coke typically involves the following steps:

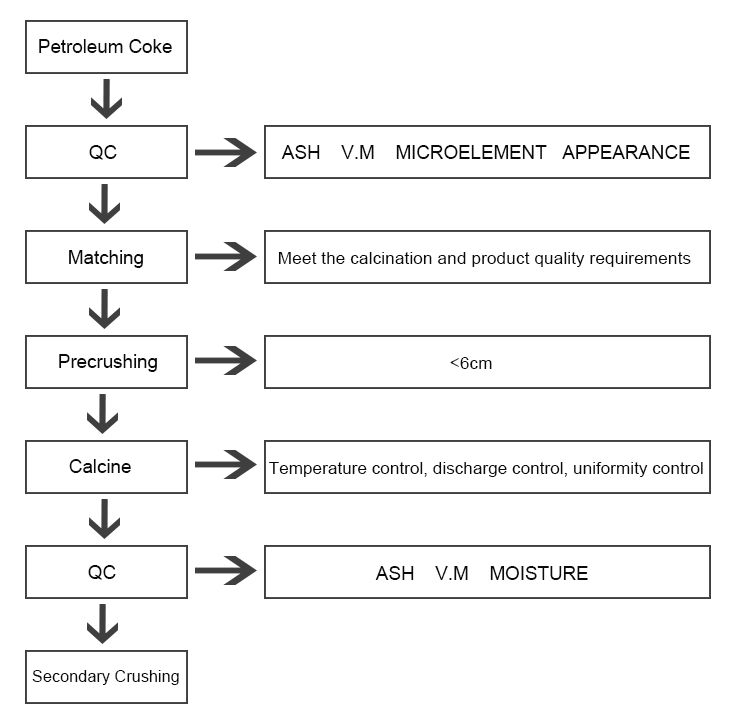

Petroleum Coke Preparation: The process starts with the preparation of petroleum coke. Petroleum coke, also known as "green coke," is a carbon-rich solid residue produced during the refining of crude oil. It is usually obtained from delayed coking units or as a byproduct of the fluid coking process.

Crushing and Drying: The petroleum coke is typically crushed and screened to remove any oversized particles. It may also undergo a drying process to reduce its moisture content, as high moisture can affect the calcination process.

Calcination: The dried petroleum coke is then subjected to high-temperature calcination in a rotary kiln or vertical shaft kiln. Calcination is a process of heating the coke to temperatures typically ranging between 1200 to 1400 degrees Celsius in the absence of air. This process drives off volatile matter and removes impurities, resulting in a denser and higher carbon content product.

Quenching: After calcination, the calcined petroleum coke is quenched with water or air to cool it down rapidly. Quenching helps to stabilize the coke and prevent further reaction or oxidation.

Screening and Crushing: The cooled calcined coke is then screened to separate it into various sizes, depending on the application requirements. It can be further crushed if necessary to achieve the desired particle size distribution.

Quality Control: Throughout the production process, quality control measures are taken to ensure that the calcined petroleum coke meets the desired specifications. This may involve conducting various tests to assess properties such as carbon content, sulfur content, ash content, volatile matter, and particle size distribution.

Packaging and Storage: The final calcined petroleum coke is packaged in bags, bulk containers, or shipped in bulk depending on the customer's requirements. It is essential to store the product in a dry and well-ventilated area to prevent reabsorption of moisture or contamination.

It's worth noting that the exact details of the production process may vary depending on the specific equipment and technology used by different manufacturers. However, the overall steps described above provide a general overview of the production process of calcined petroleum coke.

CPC role of the negative material

Calcined petroleum coke (CPC) can also play a role in negative electrode materials, specifically in certain types of batteries like lithium-ion batteries. Here's how CPC can be involved in the negative electrode:

Anode Material: In lithium-ion batteries, the negative electrode (anode) is typically made of graphite or other carbonaceous materials. Calcined petroleum coke can serve as a precursor or additive in the production of graphite-based anode materials.

Carbon Content: Similar to its role in graphite electrodes, CPC's high carbon content makes it a suitable carbonaceous material for negative electrode materials. Carbon provides the necessary electrical conductivity for the anode, allowing the flow of electrons during charge and discharge cycles.

Lithium Intercalation: The anode in lithium-ion batteries undergoes a process called intercalation, where lithium ions are inserted into the carbon structure during charging and released during discharging. Calcined petroleum coke, when properly processed and formulated, can provide a carbon matrix with desirable properties for efficient lithium intercalation and de-intercalation.

Particle Size and Structure: The properties of CPC, such as particle size and structure, can be optimized for specific battery applications. Controlling these parameters can help achieve desired characteristics like high surface area, improved lithium ion diffusion, and enhanced electrochemical performance in the negative electrode.

Stability and Cyclability: Calcined petroleum coke, when used in negative electrode materials, can contribute to the stability and cyclability of the battery. It can help maintain the structural integrity of the anode, preventing degradation and preserving the electrode's capacity over multiple charge and discharge cycles.

It's important to note that the design and composition of negative electrode materials can vary depending on the specific battery chemistry and application. While CPC can be utilized in certain types of negative electrodes, other carbonaceous materials or additives may also be incorporated to achieve desired performance characteristics.