In-depth Research On Market Of China's Calcined Coke Industry

The production process for graphite electrodes involves several steps, and calcined coke is a critical intermediate material. Here's how calcined coke is utilized in the production of graphite electrodes:

Raw material preparation: The first step is to obtain the raw materials required for the production of graphite electrodes. These raw materials typically include petroleum coke, coal tar pitch, and various additives.

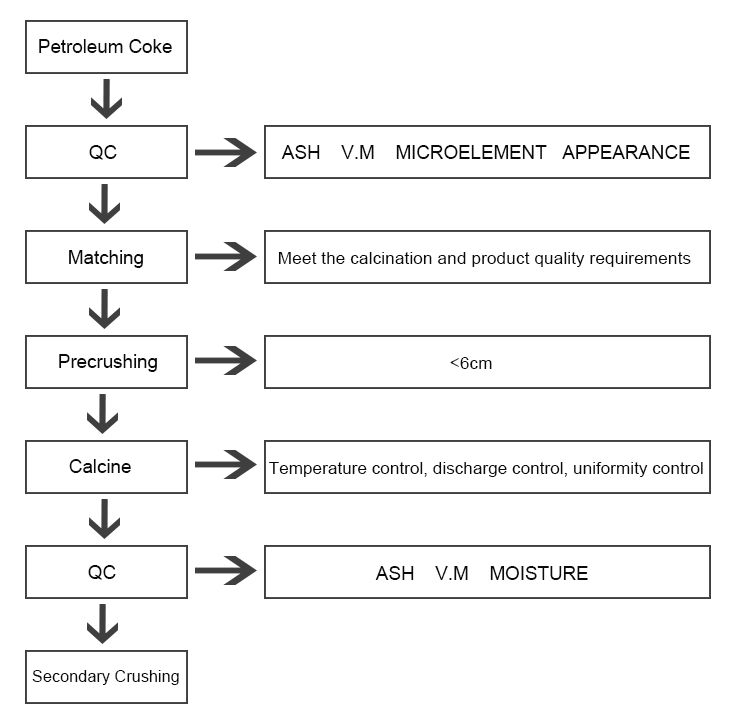

Calcination of petroleum coke: The petroleum coke is subjected to a process called calcination, which involves heating the coke at high temperatures (usually above 1200°C) in a controlled environment to remove moisture, volatile organic compounds, and other impurities. This results in calcined coke, which has a higher carbon content and is more suitable for the subsequent stages of electrode production.

Blending: The calcined coke is then carefully mixed with coal tar pitch and other additives. The blend's composition is critical as it determines the properties and characteristics of the final graphite electrode.

Forming: The blended mixture is formed into the desired electrode shape. This can be achieved through different methods, such as extrusion, vibration molding, or isostatic pressing.

Baking: The formed electrodes are then baked in high-temperature furnaces (usually around 2500-3000°C) in an inert atmosphere. This process, known as graphitization, converts the amorphous carbon in the blend into crystalline graphite, enhancing the electrode's electrical conductivity.

Machining and finishing: After graphitization, the graphite electrodes may undergo additional machining and finishing processes to achieve the required dimensions and surface quality.

Inspection and testing: The finished graphite electrodes undergo thorough inspection and testing to ensure they meet the required quality standards.

Application: Finally, the graphite electrodes are ready to be used in electric arc furnaces for the smelting of steel and other metals. They are assembled into electrode columns and inserted into the furnace, where they conduct the electrical current, generating the high temperatures necessary for the metallurgical processes.

In summary, while calcined coke is not directly used in the production of graphite electrodes, it serves as a critical raw material that undergoes specific treatments and blending to become an integral part of the graphite electrode manufacturing process.

Advantage to using Calcined Petroleum Coke in graphite electrode

Calcined coke plays a crucial role in the production of graphite electrodes, which are essential components used in electric arc furnaces (EAFs) for steelmaking and other high-temperature industrial processes. The benefits of using calcined coke in the production of graphite electrodes include:

High carbon content: Calcined coke has a high carbon content, typically above 99%. This high carbon content is essential for producing high-quality graphite electrodes, as carbon is the primary component required for their conductivity and performance.

Low electrical resistivity: Calcined coke's low electrical resistivity is a critical property for graphite electrodes. Low resistivity ensures efficient current flow through the electrode, allowing for effective and reliable heating in electric arc furnaces during the steelmaking process.

High thermal conductivity: Graphite electrodes made from calcined coke have excellent thermal conductivity. This property allows for effective heat transfer from the electrodes to the steel melt, facilitating the melting process and maintaining consistent and precise temperature control.

High mechanical strength: Calcined coke provides good mechanical strength to graphite electrodes, enabling them to withstand the mechanical stresses and vibrations experienced during the steelmaking process without cracking or breaking.

Low impurity levels: High-quality calcined coke has low impurity levels, which is critical for the production of graphite electrodes. Impurities can negatively affect the performance and durability of the electrodes, leading to reduced efficiency and increased wear and tear.

Consistent quality: The production process of calcined coke is tightly controlled, ensuring consistent properties and quality of the material. This consistency translates into uniform performance for graphite electrodes, making them more reliable during steelmaking operations.

Long electrode life: Graphite electrodes made from high-quality calcined coke have a longer lifespan, reducing the frequency of electrode replacements and the associated downtime and maintenance costs.

Better energy efficiency: The combination of low electrical resistivity and high thermal conductivity in graphite electrodes made from calcined coke leads to better energy efficiency in electric arc furnaces. This efficiency results in reduced energy consumption and cost savings during steelmaking.

Reduced environmental impact: Calcined coke used in graphite electrode production is often derived from petroleum coke, a byproduct of oil refining. Utilizing calcined coke in electrode manufacturing contributes to recycling efforts and reduces waste.

Overall, the use of calcined coke in the production of graphite electrodes provides multiple benefits, including high carbon content, low electrical resistivity, excellent thermal conductivity, and consistent quality. These properties lead to more efficient and cost-effective steelmaking processes, making graphite electrodes a vital component in modern steel production.