Difference Between Calcined Coke And Petroleum Coke

Calcined coke, or petroleum coke, finds applications in various fields due to its unique properties. Here are some common applications of calcined coke:

Aluminum Production: Calcined coke is a key ingredient in the production of carbon anodes used in the aluminum smelting process. The anodes, made from calcined coke and other materials, are responsible for conducting electricity and facilitating the electrolytic reduction of alumina into aluminum metal.

Steel Production: Calcined coke is used as a carbon source in the manufacturing of steel. It is added to iron ore and other raw materials in blast furnaces to provide the necessary carbon content for the steelmaking process. The high carbon content and energy density of calcined coke make it an efficient fuel and reducing agent.

Carbon Electrodes: Calcined coke is used in the production of carbon electrodes, which are crucial in electric arc furnaces for steel and other metal production. Carbon electrodes conduct electricity and generate the heat required for melting metals during the smelting process.

Titanium Dioxide Production: Calcined coke is used as a carbon source in the production of titanium dioxide (TiO2), a white pigment used in various applications, including paints, coatings, plastics, and paper. Calcined coke provides carbon for the chemical reaction involved in TiO2 synthesis.

Industrial Fuel: Due to its high carbon content and calorific value, calcined coke is used as a fuel source in various industrial processes. It is utilized in cement kilns, power plants, boilers, and other applications where high heat and energy are required.

Carbon Products: Calcined coke serves as a raw material for the production of various carbon-based products. It can be used to manufacture carbon electrodes for batteries, carbon brushes for electric motors, carbon filters, carbon additives in metallurgical processes, and more.

Chemical Industry: Calcined coke is used in certain chemical processes, such as the production of calcium carbide or graphite electrodes for electrochemical applications.

These are just a few examples of the diverse applications of calcined coke across different industries. Its high carbon content, low impurity levels, and energy density make it a valuable material for various manufacturing and energy-intensive processes.

Advantage to using Calcined Petroleum Coke in prebaked anode

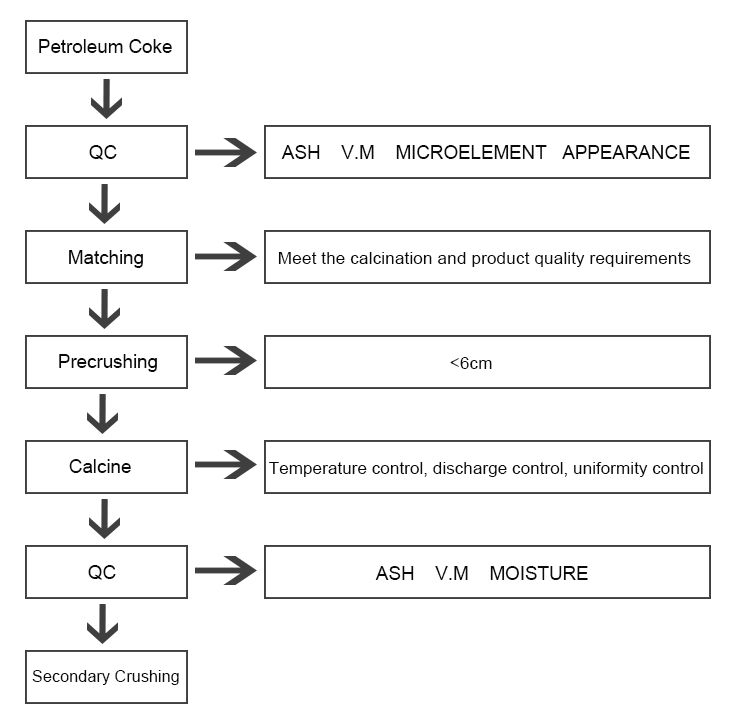

Calcined coke, also known as calcined petroleum coke, is a critical component in the production of aluminum. It is produced by heating raw petroleum coke to remove moisture, volatile matter, and other impurities, resulting in a more concentrated and pure carbon product. The use of calcined coke offers several benefits in the production of aluminum:

Improved electrical conductivity: Calcined coke has a high carbon content, which enhances its electrical conductivity. In aluminum smelting, electrical conductivity is crucial for the efficient electrolysis process, where aluminum oxide is dissolved in a molten electrolyte and reduced to aluminum metal at the cathode. The use of calcined coke as an anode material ensures efficient electrical transfer during this process.

Higher carbon content: Calcined coke typically has a higher carbon content compared to other carbon materials used in aluminum production. This increased carbon content results in a higher energy density when used as an anode in the aluminum electrolysis cells. Consequently, it requires less frequent replacement, reducing downtime and increasing overall productivity.

Low impurity content: During the calcination process, volatile matter and impurities are removed, leaving behind a cleaner carbon product. This is crucial in aluminum smelting, as impurities in the anode material can affect the quality of the aluminum produced, leading to inferior products.

Consistent quality: Calcined coke production involves precise control over the calcination process, leading to a more uniform and consistent product. The consistent quality of calcined coke is essential for stable aluminum production and helps maintain the desired operating conditions in the smelting process.

Cost-effective: While calcined coke may have a higher initial cost than some other carbon materials, its higher carbon content and longer lifespan as an anode material make it more cost-effective in the long run. The reduced frequency of anode replacements contributes to lower maintenance costs and higher overall efficiency.

Environmental benefits: The use of calcined coke in aluminum production can lead to lower greenhouse gas emissions. Due to its higher carbon content, less coke is required in the smelting process, resulting in reduced carbon dioxide emissions per ton of aluminum produced.

Recycling and sustainability: Calcined coke is often produced from petroleum coke, which is a byproduct of the oil refining process. By utilizing this material, the aluminum industry can contribute to recycling and sustainable practices by converting a waste product into a valuable resource.

In conclusion, the use of calcined coke in aluminum production provides several advantages, including improved electrical conductivity, higher carbon content, lower impurity levels, consistent quality, cost-effectiveness, and environmental benefits. It plays a vital role in the aluminum smelting process, enabling the production of high-quality aluminum products while promoting recycling and sustainability in the industry.