What's The Ferrosilicon Usage In Foundry Industry

In the foundry industry, ferrosilicon is used as an additive to improve the properties of cast iron and to aid in the casting process. Here are some common uses of ferrosilicon in the foundry industry:

Inoculation: Ferrosilicon is added to molten iron to act as an inoculant. Inoculation is a process of introducing small amounts of specific elements or compounds to promote the formation of desirable graphite structures in the cast iron. The presence of proper graphite structures, such as type A (vermicular) or type D (nodular) graphite, significantly enhances the mechanical properties and machinability of the cast iron. Ferrosilicon contains silicon, which promotes the nucleation of graphite during solidification, leading to the desired graphite morphology.

Nodularization: Ferrosilicon is used to produce nodular or ductile iron. In nodular iron production, a carefully controlled amount of magnesium is added to the molten iron along with ferrosilicon. The magnesium reacts with the silicon in ferrosilicon to form magnesium silicides, which then promote the formation of nodules or spheroidal graphite in the cast iron. Nodular iron has excellent mechanical properties and is widely used in various engineering applications due to its high tensile strength, ductility, and toughness.

Vermicular graphite formation: In some cases, ferrosilicon is used in combination with other alloying elements to produce vermicular graphite or compacted graphite iron. This type of cast iron exhibits a unique microstructure between the flake-like graphite of gray iron and the spheroidal graphite of nodular iron. Vermicular graphite iron combines good strength and ductility, making it suitable for certain critical components in automotive and engineering industries.

Graphite modification: Besides influencing the graphite morphology, ferrosilicon can also be used to modify the graphite flakes in gray iron. It helps to refine and distribute the graphite, resulting in improved mechanical properties and reduction of casting defects.

Thermal expansion control: Ferrosilicon can be added to control the thermal expansion properties of cast iron. By adjusting the silicon content, foundries can tailor the coefficient of thermal expansion of cast iron to match the requirements of specific applications, such as engine blocks and cylinder heads in automotive industries.

Overall, the use of ferrosilicon in the foundry industry is essential for achieving the desired microstructure and mechanical properties in cast iron. Its versatility in modifying the graphite morphology and controlling other aspects of cast iron properties makes it a valuable additive in various foundry applications.

What's The Benefit To Using Ferrosilicon In Foundry Industry

Using ferrosilicon in the foundry industry offers several important benefits that improve the casting process and the properties of the final castings. Some of the main advantages of using ferrosilicon in the foundry industry include:

Inoculation: Ferrosilicon is widely used as an inoculant in the foundry industry. Inoculation is a process where small amounts of ferrosilicon are added to molten metal just before casting. The ferrosilicon helps in promoting the formation of fine graphite flakes or nodules in cast iron, depending on the specific application. Fine graphite distribution in cast iron improves the mechanical properties of the castings, such as increased strength, hardness, and wear resistance. It also reduces the risk of defects like chill and enhances the overall quality of the castings.

Nodularization: Ferrosilicon is utilized in the nodularization process to produce nodular or ductile cast iron. The addition of ferrosilicon in combination with other elements, such as magnesium (in the form of ferromagnesium), helps in the formation of graphite nodules in the cast iron. Nodular cast iron offers superior mechanical properties compared to grey cast iron, including higher tensile strength, elongation, and impact resistance. This makes nodular cast iron more suitable for a wide range of applications, including automotive components, pipes, fittings, and machine parts.

Grain refinement: Ferrosilicon aids in grain refinement during solidification. It promotes the formation of finer and more uniform grain structures in castings, leading to improved mechanical properties and better workability.

Controlling shrinkage defects: The use of ferrosilicon in the foundry process helps reduce shrinkage defects in castings. Shrinkage defects occur when the molten metal contracts during solidification, leading to voids or cracks in the final casting. Ferrosilicon's role in promoting finer and more uniform microstructures helps minimize such defects and enhances the overall quality of the castings.

Cost-effectiveness: Ferrosilicon is a cost-effective additive in the foundry industry. It provides significant benefits in improving casting properties while being readily available at reasonable prices.

Process efficiency: Ferrosilicon has good fluidity at elevated temperatures, making it easy to mix and distribute within the molten metal during the casting process. This ensures uniform distribution of silicon, leading to consistent material properties in the castings.

The use of ferrosilicon in the foundry industry contributes to producing high-quality castings with improved mechanical properties and fewer defects. It enhances the efficiency of the casting process and allows foundries to create a wide range of castings suitable for various industrial applications.

Specification

Quality inspection certificate of finished product | |||

Product name | Ferro Silicon | Batch No. | ZC2023-06-13 |

Sampling Site | / | Product specifications | / |

Acceptance date | 2023.06.13 | Report date | 2023.06.14 |

Test items | SH/T 0313-92 | Test results | |

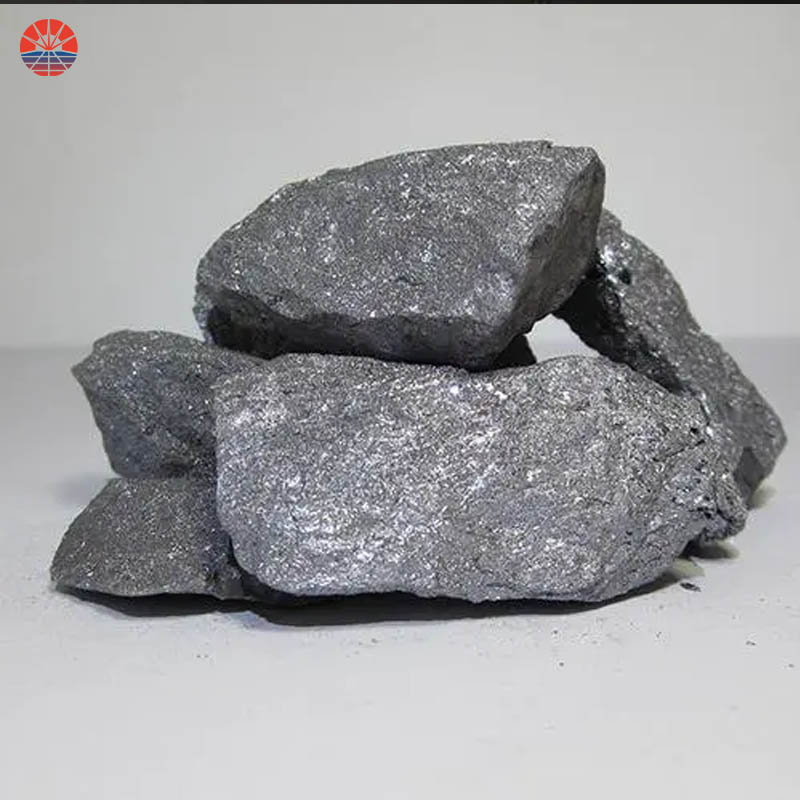

Appearance | This product should be black solid | ||

Si | 75.32 | ||

c | 0.11 | ||

P | 0.03 | ||

s | 0.014 | ||

A1 | 0.77 | ||

Conclusion | Product conforms to specification. | ||