Calcined Petroleum Coke Manufacturing Process

Calcined Petroleum Coke (CPC) is a crucial raw material used in the production of aluminum and steel. The manufacturing process involves several key steps. Initially, raw petroleum coke is heated in a rotary kiln at high temperatures (above 1200°C) to remove volatile compounds and moisture. This process, known as calcination, transforms the raw material into a more stable and energy-dense form.

The calcined coke is then cooled and classified into different particle sizes based on its intended application. The quality of CPC depends on factors like the source of raw petroleum coke, calcination conditions, and the efficiency of subsequent handling processes.

CPC finds extensive use in the aluminum industry as an anode material during the smelting process. It provides the necessary carbon for the reduction of alumina to aluminum. Additionally, CPC is utilized in the steel industry for carburization purposes, enhancing the carbon content in steel production.

The entire manufacturing process is designed to produce high-quality Calcined Petroleum Coke with the required physical and chemical properties to meet the stringent demands of various industrial applications.

Calcined Petroleum Coke Manufacturing Process

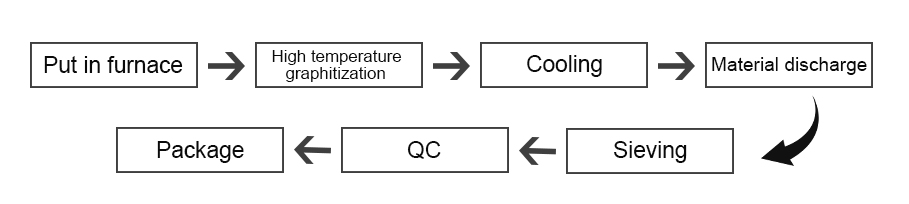

The manufacturing process of Calcined Petroleum Coke (CPC) involves several steps:

1. **Raw Material Preparation:**

Raw petroleum coke, a byproduct of the oil refining process, is selected as the starting material. The quality of raw coke significantly influences the quality of the final CPC.

2. **Crushing and Grinding:**

The raw coke is crushed and ground into fine particles to facilitate efficient heating during the calcination process. This step helps in achieving a uniform particle size distribution.

3. **Drying:**

The crushed and ground coke is typically dried to remove excess moisture. The drying process is crucial to prevent issues during the subsequent calcination phase.

4. **Calcination:**

The dried coke is then subjected to high temperatures in a rotary kiln (typically above 1200°C) in the presence of air or inert gases. This process, known as calcination, removes volatile components and moisture, transforming the raw coke into a more stable and high-carbon material.

5. **Cooling:**

The calcined coke is cooled either in a rotary cooler or a vertical cooler. This cooling step is essential to stabilize the material and prepare it for subsequent handling and storage.

6. **Screening and Sizing:**

The cooled CPC is often screened and sized to meet specific customer requirements. This step ensures uniformity in particle size distribution and desired physical properties.

7. **Quality Control:**

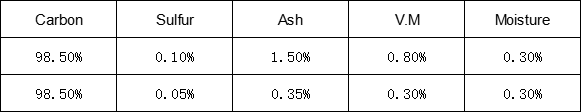

Rigorous quality control measures are implemented throughout the manufacturing process to monitor and ensure that the CPC meets industry standards and customer specifications.

8. **Storage and Packaging:**

The final product is stored in bins or silos to await packaging. CPC is often packaged in bulk containers or bags for ease of transportation and handling.

The entire manufacturing process is designed to produce high-quality Calcined Petroleum Coke with the required physical and chemical properties, making it suitable for various industrial applications, particularly in the aluminum and steel industries.