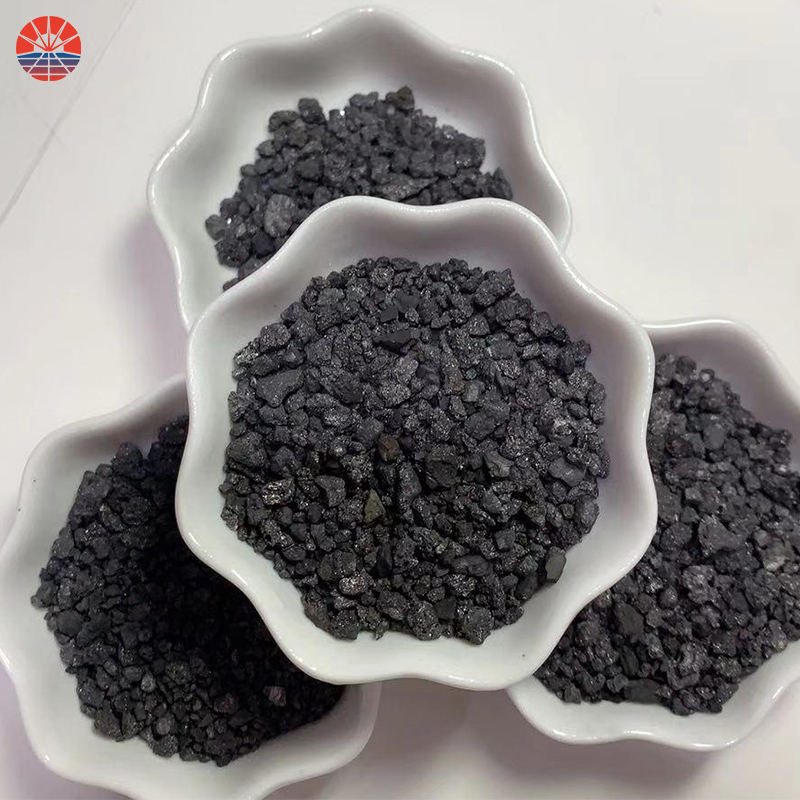

Production Technology Of Graphitized Petroleum Coke

Using graphitized petroleum coke (GPC) in negative electrode materials for various applications, particularly in lithium-ion batteries, offers several advantages. Here are some key benefits:

High Carbon Content: GPC typically has a high carbon content, often exceeding 98%. This high carbon content provides a concentrated source of carbon for the negative electrode material. It ensures sufficient capacity for lithium storage and promotes efficient electrochemical performance.

Graphitic Structure: GPC undergoes a graphitization process that transforms the amorphous carbon structure into a highly ordered and crystalline graphite structure. This graphitic structure provides several advantages, including improved electrical conductivity, enhanced lithium diffusion kinetics, and increased stability during lithiation and delithiation cycles.

Excellent Electrical Conductivity: The highly graphitic structure of GPC results in excellent electrical conductivity. This property facilitates efficient electron transfer during the charge and discharge processes in lithium-ion batteries. Enhanced electrical conductivity ensures low internal resistance, reduced energy losses, and improved overall battery performance.

Superior Lithium Intercalation/Deintercalation: GPC's graphitic structure enables efficient intercalation and deintercalation of lithium ions during battery operation. The well-ordered carbon layers provide sites for lithium ion insertion, allowing for faster and more reversible lithium-ion intercalation and deintercalation processes. This leads to improved capacity, cycling stability, and rate capability of the negative electrode material.

Thermal Stability: GPC exhibits high thermal stability, which is crucial for battery safety. During battery operation or in high-temperature environments, GPC maintains its structural integrity, minimizing the risk of thermal runaway or electrode degradation. The thermal stability of GPC contributes to the overall safety and reliability of lithium-ion batteries.

Low Impurity Content: GPC is processed to have low impurity levels, including sulfur, nitrogen, and volatile matter. This low impurity content reduces the risk of unwanted side reactions, electrode deterioration, and capacity losses. It helps maintain the purity and stability of the negative electrode material, ensuring high performance and longevity of lithium-ion batteries.

Cost-Effectiveness: GPC is a cost-effective choice as a carbon precursor for negative electrode materials. Its availability, efficient production processes, and desirable properties make it a favorable option for commercial-scale battery production. GPC offers a balance of cost and performance, contributing to the cost optimization of lithium-ion batteries.

Overall, the advantages of using graphitized petroleum coke in negative electrode materials lie in its high carbon content, graphitic structure, excellent electrical conductivity, lithium intercalation capabilities, thermal stability, low impurity content, and cost-effectiveness. These properties contribute to improved battery performance, enhanced cycling stability, increased energy storage capacity, and extended battery lifespan.

Graphitized petroleum coke Role in negative electrode materials

Graphitized petroleum coke is not typically used directly as a negative electrode material. Instead, it is commonly used as a carbon precursor in the production of negative electrode materials, particularly in lithium-ion batteries. Here's an explanation of its role in this context:

Carbon Precursor: Graphitized petroleum coke serves as a carbon precursor for the negative electrode (anode) material in lithium-ion batteries. The coke is subjected to further processing steps to transform it into an active anode material.

Carbonization: The graphitized petroleum coke undergoes a process called carbonization, where it is heated at high temperatures in an inert atmosphere. This step helps to remove volatile components and further increase the carbon content and structural stability of the material.

Coating and Composite Formation: The carbonized coke may undergo additional treatments, such as coating with binder materials and mixing with other active components. These processes help to enhance the electrochemical performance and stability of the negative electrode material.

Lithiation and Delithiation: Once the graphitized petroleum coke has been transformed into an active anode material, it can undergo the lithiation and delithiation cycles during battery operation. During the charging process, lithium ions are intercalated into the carbon structure of the anode, storing energy. In the discharge process, the lithium ions are released, generating a flow of electrons for powering devices.

The role of graphitized petroleum coke in negative electrode materials lies in its ability to provide a carbon framework that can accommodate the intercalation and deintercalation of lithium ions during the battery's charge and discharge cycles. Its high carbon content, graphitic structure, and stability make it suitable for this purpose.

It's important to note that in addition to graphitized petroleum coke, other carbon materials, such as synthetic graphite, natural graphite, and carbon black, are also commonly used as negative electrode materials in lithium-ion batteries. The choice of carbon precursor depends on the specific requirements of the battery application, including energy density, cycling performance, and cost considerations.