The Benefits To Using Needle Coke In Graphite Electrode

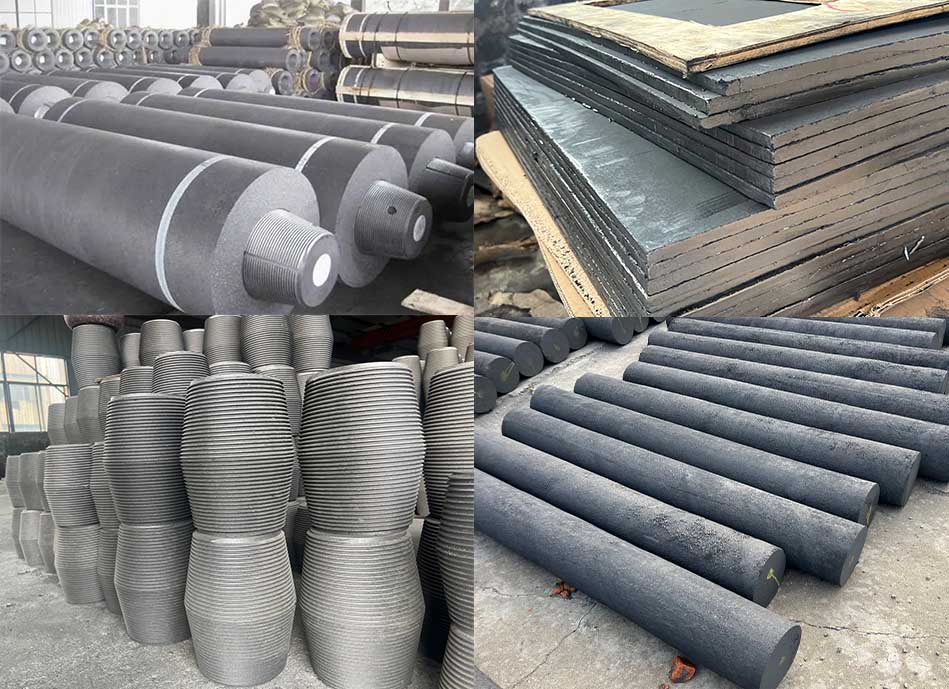

Using needle coke in graphite electrodes offers several benefits due to its unique properties and structure. Graphite electrodes are essential components used in electric arc furnaces (EAFs) for steelmaking and other high-temperature industrial processes. Here are the benefits of using needle coke in graphite electrodes:

High Thermal Conductivity: Needle coke has a well-aligned, needle-like structure with high thermal conductivity. This allows for efficient heat transfer during the steelmaking process, enabling better melting of scrap metal and improving the overall energy efficiency of the electric arc furnace.

Low Electrical Resistance: Graphite electrodes made from needle coke have low electrical resistance. This means they can efficiently conduct electrical current, which is crucial for maintaining a stable and strong arc in the EAF during steelmaking.

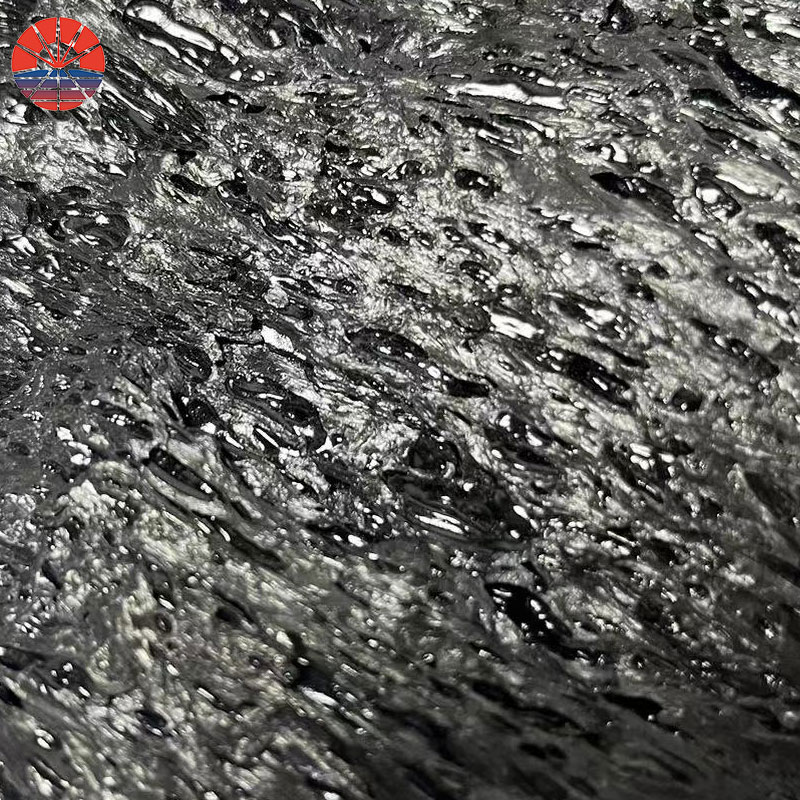

High Carbon Content: Needle coke has a very high carbon content, typically exceeding 97% or even higher. This high purity of carbon is essential for graphite electrodes, as it ensures high electrical conductivity and minimizes undesirable chemical reactions during the steelmaking process.

Low Coefficient of Thermal Expansion: Needle coke-based graphite electrodes have a low coefficient of thermal expansion, meaning they expand very little when exposed to high temperatures. This property helps maintain the structural integrity of the electrodes during the repeated heating and cooling cycles in the EAF.

Superior Mechanical Strength: Graphite electrodes made from needle coke exhibit excellent mechanical strength, allowing them to withstand the mechanical stresses and loads experienced during the steelmaking process.

Resistance to Oxidation: Needle coke-based graphite electrodes have good resistance to oxidation at high temperatures. This makes them more durable and ensures a longer electrode lifespan in the demanding conditions of steelmaking.

Consistency and Homogeneity: Needle coke provides uniform properties throughout the bulk of the graphite electrodes, resulting in consistent performance and reliable steelmaking operations.

Increased Efficiency and Productivity: The unique properties of needle coke-based graphite electrodes contribute to higher efficiency and productivity in electric arc furnace steelmaking. They enable faster melting rates, better temperature control, and reduced electrode consumption, resulting in cost savings and improved overall steelmaking performance.

It's important to note that needle coke is a specialty product and is relatively expensive compared to other forms of petroleum coke. The production of high-quality needle coke requires precise control of the coking process to achieve the desired crystal structure and properties. Therefore, the choice of graphite electrode material, including the type of coke used, is critical in optimizing the performance and cost-effectiveness of electric arc furnace steelmaking processes.

The Role Of Using Needle Coke In Graphite Electrode

The role of using needle coke in graphite electrodes is crucial to their performance and effectiveness in electric arc furnaces (EAFs) for steelmaking. Needle coke, with its unique properties and structure, is the preferred material for manufacturing high-quality graphite electrodes. Here's the role of needle coke in graphite electrodes:

High Thermal Conductivity: Needle coke has a needle-like structure with highly aligned carbon fibers. This structure provides excellent thermal conductivity, allowing graphite electrodes to efficiently transfer heat during the steelmaking process. As the electric arc generates intense heat, the high thermal conductivity of needle coke helps maintain the necessary temperature for melting scrap metal and producing molten steel.

Low Electrical Resistance: The aligned carbon fibers and high carbon content in needle coke result in low electrical resistance. Low electrical resistance allows graphite electrodes to conduct electrical current efficiently, leading to an energy-efficient operation of the EAF.

High Purity and Low Impurities: Needle coke has a high carbon purity and low levels of impurities like ash and sulfur. The purity is essential in preventing unwanted chemical reactions during the steelmaking process, ensuring stable and reliable performance of the graphite electrodes over time.

Mechanical Strength and Dimensional Stability: The unique structure of needle coke provides mechanical strength to the graphite electrodes, allowing them to withstand the mechanical stresses and vibrations experienced during EAF operation. Additionally, the low coefficient of thermal expansion of needle coke helps maintain the dimensional stability of the graphite electrodes during high-temperature operations, minimizing the risk of cracking or deformation.

Longer Electrode Life: The combination of low electrical resistance, high purity, and mechanical strength results in longer electrode life. Graphite electrodes made with needle coke can endure more heat cycles before needing replacement, reducing downtime and maintenance costs.

Consistent Performance: Needle coke's uniform properties and homogeneity contribute to the consistent performance of graphite electrodes. This ensures stable and predictable steelmaking processes, leading to higher steel quality and productivity.

Improved Steel Quality: The use of high-quality graphite electrodes made from needle coke leads to improved steel quality due to better temperature control and precise operation in the EAF. Consistent and efficient heat transfer ensures the desired chemical composition and metallurgical properties of the produced steel.

In summary, needle coke plays a critical role in the performance of graphite electrodes by providing high thermal conductivity, low electrical resistance, high purity, and mechanical strength. These properties collectively contribute to efficient and reliable steelmaking in electric arc furnaces, making needle coke the preferred material for manufacturing high-performance graphite electrodes used in the steel industry.