How Is Needle Coke Manufactured

A good needle coke is a high-quality, premium-grade form of petroleum coke that possesses specific characteristics and properties ideal for its intended applications, such as in the production of graphite electrodes for electric arc furnaces (EAFs) and anodes for the aluminum industry. Here are some key attributes of a good needle coke:

High Carbon Content: A good needle coke should have a very high carbon content, typically exceeding 97% or even higher. This high purity of carbon is essential for its applications in high-temperature processes.

Low Impurities: It should have low levels of impurities like ash, sulfur, and metals. Low impurity levels are crucial to ensure efficient performance and minimize undesirable chemical reactions during the application.

Needle-Like Structure: The carbon fibers in a good needle coke should have a well-aligned, needle-like structure. This unique morphology gives it its name and contributes to its exceptional properties, such as high thermal conductivity and low coefficient of thermal expansion.

Superior Thermal Conductivity: A good needle coke should exhibit high thermal conductivity, allowing for efficient heat transfer during its application. This property is particularly important for applications involving extreme temperatures, such as in electric arc furnaces and aluminum electrolysis cells.

Low Coefficient of Thermal Expansion: It should have a low coefficient of thermal expansion, meaning it expands very little when exposed to high temperatures. This property is crucial for maintaining the structural integrity of components made from needle coke during high-temperature operations.

High Electrical Conductivity: A good needle coke should have excellent electrical conductivity, enabling efficient electron transport during its application. This is vital for applications such as graphite electrodes in EAFs, where electrical current must flow efficiently for steelmaking.

Consistency and Homogeneity: A good needle coke should exhibit uniform properties throughout its bulk, ensuring consistent performance in the final products.

Availability and Supply: A good needle coke should be produced in sufficient quantities and be readily available in the market to meet the demands of various industries.

It's important to note that needle coke is a specialty product and relatively expensive compared to other forms of petroleum coke. The production of high-quality needle coke requires precise control of the coking process to achieve the desired crystal structure and properties. As a result, needle coke is produced in limited quantities, and its availability can be subject to fluctuations in the market demand and supply.

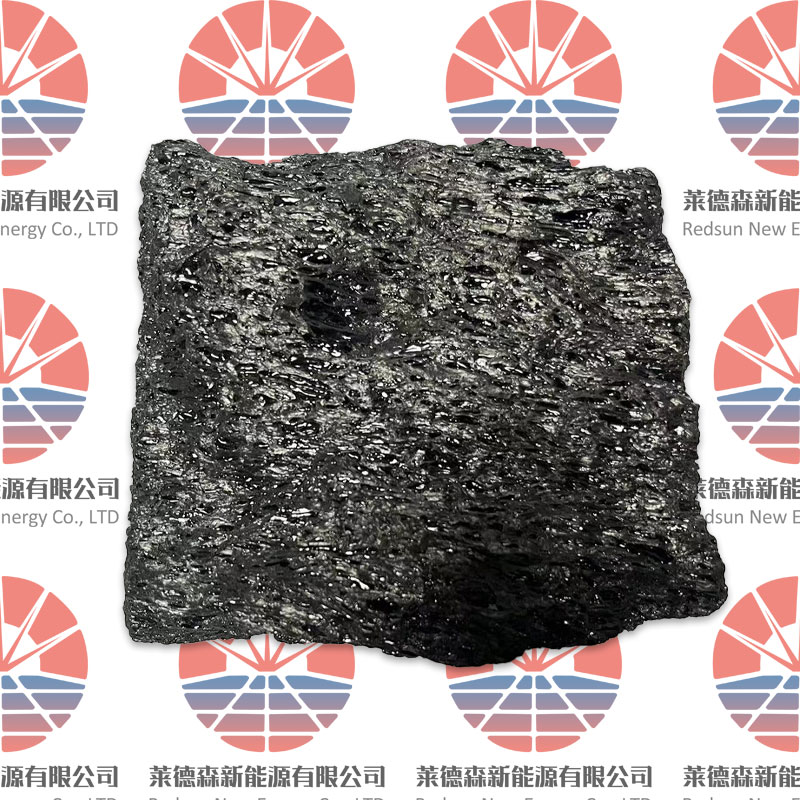

What Is Needle Coke

Needle coke is a premium-grade form of petroleum coke with specific physical and chemical properties that make it suitable for certain specialized applications. It is named "needle" coke due to its distinctive needle-like structure, which consists of long, thin, and well-aligned carbon fibers.

The production of needle coke involves a unique and precise thermal cracking process of specific heavy petroleum feedstocks, such as decant oil or slurry oil, in a coking unit. The coking process is carefully controlled to achieve the desired crystal structure and properties required for various applications.

Key characteristics of needle coke include:

High Carbon Content: Needle coke has a very high carbon content, typically exceeding 97% or even higher. This high carbon purity is a critical factor for its applications in high-temperature processes.

Low Ash and Sulfur Content: Needle coke has low levels of impurities like ash and sulfur, which are essential for applications that require high-purity carbon material.

High Thermal Conductivity: The needle-like structure of the carbon fibers allows for efficient heat transfer and high thermal conductivity, making it suitable for applications involving extreme temperatures.

Low Coefficient of Thermal Expansion: Needle coke has a low coefficient of thermal expansion, meaning it expands very little when exposed to high temperatures. This property is vital for applications requiring dimensional stability at high temperatures.

Due to its specific properties, needle coke is highly sought after for certain industrial applications. The primary uses of needle coke are in the production of graphite electrodes used in electric arc furnaces for steelmaking and anodes for the aluminum industry. In both cases, the high thermal conductivity, low electrical resistance, and ability to withstand extreme temperatures make needle coke an essential component for efficient and reliable operations.

It's important to note that needle coke is considered a premium-grade petroleum coke and is more expensive than other forms of petroleum coke. Additionally, the production of needle coke is limited and can be subject to fluctuations in the market demand and supply.