Needle Coke Production Process

Using needle coke in the production of graphite electrodes offers several significant benefits due to its unique properties and structure. Graphite electrodes are crucial components used in electric arc furnaces (EAFs) for steelmaking, where they conduct electrical current and enable the conversion of scrap metal into molten steel. Here are some of the advantages of using needle coke in graphite electrodes:

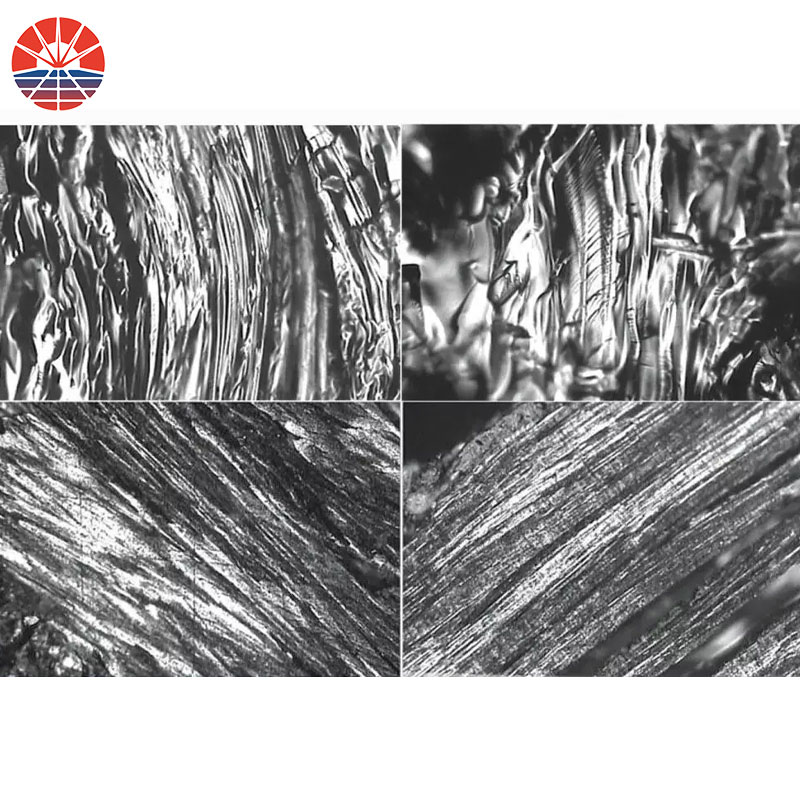

High Thermal Conductivity: Needle coke's needle-like structure and high thermal conductivity allow for efficient heat transfer during the steelmaking process. This property ensures that the electric arc furnace operates at the high temperatures required for melting scrap metal and producing molten steel.

Low Electrical Resistance: The high carbon content and aligned carbon fibers in needle coke result in low electrical resistance in graphite electrodes. Low electrical resistance allows for efficient passage of electrical current through the electrodes, making the EAF process more energy-efficient.

High Purity and Low Impurities: Needle coke has high carbon purity and low levels of impurities like ash and sulfur. This high purity is critical for graphite electrodes, as it helps to minimize unwanted chemical reactions during the steelmaking process, ensuring better performance and longer electrode lifespan.

Mechanical Strength and Low Coefficient of Thermal Expansion: The unique structure of needle coke contributes to the mechanical strength of graphite electrodes. This strength is essential to withstand the mechanical stresses and vibrations experienced during EAF operation. Additionally, the low coefficient of thermal expansion of needle coke helps maintain the dimensional stability of graphite electrodes during high-temperature operations, reducing the risk of cracking or deformation.

Longer Electrode Life: The combination of low electrical resistance, high purity, and mechanical strength results in longer electrode life. Graphite electrodes made with needle coke can endure more heat cycles before needing replacement, reducing downtime and production costs.

Consistent Performance: Needle coke's uniform properties and homogeneity contribute to the consistent performance of graphite electrodes, ensuring stable and predictable steelmaking processes.

Improved Steel Quality: The use of high-quality graphite electrodes made from needle coke can lead to improved steel quality due to better temperature control and precise operation in the EAF.

Increased Energy Efficiency: The combination of low electrical resistance and high thermal conductivity in needle coke-based graphite electrodes helps reduce energy consumption during steelmaking, leading to increased energy efficiency and cost savings.

It's important to note that needle coke is a specialized and premium-grade material, making it relatively expensive compared to other forms of petroleum coke. The availability of needle coke can be subject to fluctuations in the market, which can impact its cost and supply for graphite electrode manufacturers. However, despite the higher cost, the use of needle coke in graphite electrodes is preferred for its superior performance and efficiency in the demanding steelmaking process.

The Role Of Using Needle Coke In Graphite Electrode

The use of needle coke in the production of graphite electrodes plays a crucial role in enhancing the performance and efficiency of these critical components in electric arc furnaces (EAFs) used for steelmaking. Here's the role of using needle coke in graphite electrodes:

High Thermal Conductivity: Needle coke's unique needle-like structure and high thermal conductivity allow for efficient heat transfer during the steelmaking process. Graphite electrodes made from needle coke efficiently conduct the heat generated by the electric arc, ensuring that the EAF operates at the high temperatures required for melting scrap metal and producing molten steel.

Low Electrical Resistance: The high carbon content and aligned carbon fibers in needle coke result in low electrical resistance in graphite electrodes. This property enables efficient passage of electrical current through the electrodes, facilitating the conversion of electrical energy into heat, which is crucial for the steelmaking process.

High Purity and Low Impurities: Needle coke has high carbon purity and low levels of impurities like ash and sulfur. The high purity of needle coke is essential for graphite electrodes, as it helps to minimize unwanted chemical reactions during the steelmaking process, ensuring better performance and longer electrode lifespan.

Mechanical Strength and Dimensional Stability: The unique structure of needle coke contributes to the mechanical strength of graphite electrodes. This strength is vital to withstand the mechanical stresses and vibrations experienced during EAF operation. Additionally, the low coefficient of thermal expansion of needle coke helps maintain the dimensional stability of graphite electrodes during high-temperature operations, reducing the risk of cracking or deformation.

Longer Electrode Life: The combination of low electrical resistance, high purity, and mechanical strength results in longer electrode life. Graphite electrodes made with needle coke can endure more heat cycles before needing replacement, reducing downtime and production costs.

Consistent Performance: Needle coke's uniform properties and homogeneity contribute to the consistent performance of graphite electrodes, ensuring stable and predictable steelmaking processes.

Improved Steel Quality: The use of high-quality graphite electrodes made from needle coke can lead to improved steel quality due to better temperature control and precise operation in the EAF.

Overall, needle coke is a critical component in the production of high-performance graphite electrodes. Its unique properties, such as high thermal conductivity, low electrical resistance, high purity, and mechanical strength, make it the preferred choice for demanding steelmaking processes in electric arc furnaces. Despite its higher cost compared to other forms of petroleum coke, the benefits of using needle coke in graphite electrodes justify its use in steelmaking industries to achieve more efficient and effective steel production.