Petroleum coke production process

Petroleum coke, often abbreviated as petcoke, is a carbon-rich solid material that is a byproduct of the oil refining process. The production of petroleum coke involves several stages in the refining of crude oil. Here is an overview of the petroleum coke production process:

Crude Oil Refining: The production of petroleum coke begins with the refining of crude oil in an oil refinery. Crude oil is a complex mixture of hydrocarbons, and the refining process involves separating these hydrocarbons into various components based on their boiling points and properties.

Atmospheric Distillation: The first step in crude oil refining is atmospheric distillation. In this process, crude oil is heated and vaporized in a distillation column. As the vapors rise through the column, they cool and condense at different heights, based on their boiling points. This separation process results in various fractions, including gasoline, diesel, jet fuel, and heavier residual oil.

Vacuum Distillation: The heavier residual oil obtained from atmospheric distillation is further processed in a vacuum distillation unit. This process operates at lower pressures to separate the heavier components, which have higher boiling points, from the lighter fractions.

Coking: The heaviest residual oil fraction obtained from vacuum distillation, known as "bottoms" or "residuum," contains high concentrations of carbon and other impurities. To extract more valuable products from this residue, it undergoes coking. Coking is a thermal cracking process that breaks down the large, complex hydrocarbon molecules into smaller ones, mainly consisting of carbon atoms.

Delayed Coking: The most common method of coking used in the production of petroleum coke is called delayed coking. In this process, the residual oil is heated to very high temperatures (typically around 900 to 930°C or 1652 to 1706°F) in large drums or coke drums. The intense heat causes thermal cracking of the heavy hydrocarbons, leaving behind a solid carbon-rich material, which is petroleum coke. The volatile components and lighter hydrocarbons are separated and recovered as other refinery products.

Coke Drum Cooling: Once the coking process is complete, the coke drums are then allowed to cool. Water or air may be used to cool the drums and solidify the petroleum coke.

Cutting and Handling: After cooling, the solidified petroleum coke is cut into manageable pieces using high-pressure water jets or mechanical cutters. The resulting petroleum coke is then handled, stored, and transported to various industries for further processing or utilization.

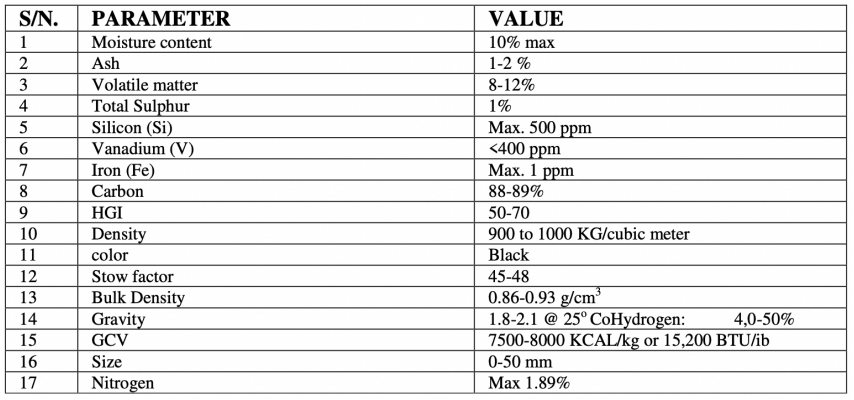

It is important to note that the properties of petroleum coke, including its carbon content, sulfur content, and other characteristics, can vary based on the crude oil feedstock and the specific coking process employed by the refinery. As a result, the quality and applications of petroleum coke can differ depending on these factors.

Petroleum coke usage

Petroleum coke (petcoke) is a carbon-rich solid material that finds various applications across different industries. Its usage includes the following:

Fuel in Power Plants: Petcoke is used as a fuel source in some power plants, particularly in regions where it is abundant and cost-effective. It provides high calorific value and can be used as a supplementary fuel along with coal or natural gas for electricity generation.

Cement Industry: Petcoke is used as a source of energy and carbon in the cement manufacturing process. Its high carbon content makes it an efficient fuel for providing heat in the cement kilns, reducing energy costs.

Steel Industry: Petcoke is utilized as a fuel in steel mills to provide heat for the production of iron and steel. It serves as a reducing agent in the blast furnace process, converting iron ore into molten iron.

Aluminum Industry: In the aluminum smelting process, petcoke is used as a source of carbon for carbon anodes. These anodes are essential in the Hall-Héroult electrolytic process, where aluminum is extracted from alumina.

Brick and Glass Manufacturing: Petcoke can be used as a fuel in brick and glass kilns to provide high temperatures for shaping and melting processes.

Refractory Industry: Petcoke is used in the production of refractory materials, which are essential for high-temperature applications in industries such as steelmaking and cement.

Carbon Electrodes: Petcoke is used in the production of carbon electrodes for electric arc furnaces, where it acts as a conductive material.

Foundries: Petcoke is used in foundries for metal casting processes as a carbon additive to enhance the metal properties.

Titanium Dioxide Production: In the titanium dioxide industry, petcoke is used as a carbon source in the chlorination process.

It is important to note that the use of petroleum coke has environmental and health implications due to its high carbon content and potential emissions of greenhouse gases and other pollutants. Hence, the usage of petcoke in various industries is subject to regulatory scrutiny and environmental standards. As concerns about climate change and air pollution increase, some industries are exploring cleaner and more sustainable alternatives to reduce their reliance on petcoke.