What is the raw material of calcined coke

The raw material for calcined coke is petroleum coke, often abbreviated as "pet coke." Petroleum coke is a carbon-rich solid material that is a byproduct of the oil refining process. It's derived from the thermal cracking of heavy crude oil fractions during the refining process. This residue contains a significant amount of carbon and is composed of hydrocarbon compounds.

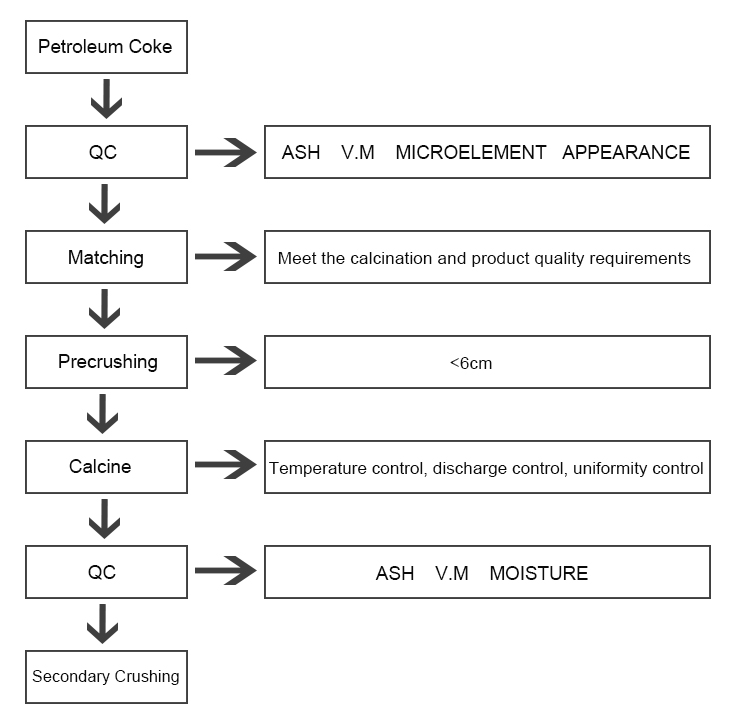

Petroleum coke is initially produced as a solid residue from the distillation of crude oil in a refinery's coker units. This raw material is then further processed through a heat treatment process called "calcination." Calcination involves subjecting the petroleum coke to elevated temperatures, typically in the range of 1200 to 1400 degrees Celsius (2192 to 2552 degrees Fahrenheit), in order to remove volatile components and impurities. This process transforms the petroleum coke into calcined coke, which has a higher carbon content and improved properties suitable for various industrial applications, including aluminum production, as discussed earlier.

The greatest use of calcined coke

The greatest use of calcined coke is in the production of carbon anodes for the aluminum smelting industry. Carbon anodes are essential components in the electrolytic reduction process used to produce aluminum from alumina (aluminum oxide) in electrolytic cells called potlines. Calcined coke is a critical ingredient in the manufacturing of these carbon anodes due to its high carbon content, low impurity levels, and suitable physical properties.

During the aluminum smelting process, carbon anodes are placed in the electrolytic cells and serve as conductive surfaces where electrochemical reactions occur. The anodes release electrons, which flow through the cell to the alumina, reducing it to aluminum metal. This process is vital for extracting aluminum from its ore, and high-quality anodes made from calcined coke are crucial for efficient and cost-effective aluminum production.

Calcined coke's properties, including its high carbon content and low impurity levels, enable the anodes to maintain their structural integrity and electrical conductivity under the demanding conditions within the electrolytic cells. This results in consistent and efficient aluminum smelting operations.

While there are other uses for calcined coke in various industries such as steel, titanium dioxide production, and more, its primary and most significant use remains in the aluminum industry as a key component in the production of carbon anodes.