What Is Ferrosilicon

Ferrosilicon is an alloy of iron and silicon, typically containing 15% to 90% silicon by weight. It is commonly used in various industrial applications due to its unique properties:

Deoxidizer: Ferrosilicon is often added to molten steel and iron to remove oxygen and other impurities. It helps improve the quality of the final product by reducing the levels of undesirable elements.

Alloying Agent: Ferrosilicon is used as an alloying agent in the production of various steel and iron alloys. Depending on the silicon content, it can modify the properties of the base metal, such as increasing its strength or altering its magnetic properties.

Inoculant: In the casting of iron and steel, ferrosilicon can act as an inoculant. It promotes the formation of graphite in cast iron, which enhances its machinability and reduces brittleness.

Reducing Agent: Ferrosilicon can serve as a reducing agent in metallurgical processes, helping to reduce certain metal oxides to their pure metal forms.

Semiconductor Industry: High-purity ferrosilicon is used in the semiconductor industry for the production of silicon wafers, which are a crucial component in the manufacture of integrated circuits and other electronic devices.

Ferrosilicon comes in various grades and silicon concentrations to suit specific applications. The choice of grade depends on the desired outcome and the specific needs of the industrial process.

The Production Process Of Ferrosilicon

The production process of ferrosilicon involves the reduction of silica (usually in the form of quartz) with iron in an electric arc furnace. The process is high-temperature and energy-intensive. Here are the steps involved in the production of ferrosilicon:

1. **Raw Material Preparation:** The primary raw materials used in ferrosilicon production are silica (SiO2) and iron (Fe). Silica is commonly obtained from quartz, while iron can be sourced from iron ore, iron scrap, or other iron-containing materials. The raw materials need to be properly sized and prepared before they are introduced into the furnace.

2. **Furnace Charging:** The prepared raw materials, typically quartz and iron scrap, are charged into an electric arc furnace. The proportions of silica and iron used depend on the desired grade of ferrosilicon.

3. **Melting and Reduction:** Inside the electric arc furnace, an intense electric arc is generated between carbon electrodes and the raw materials. The high temperatures generated by the arc (often exceeding 2,000°C or 3,600°F) cause the silica to reduce to silicon, and the iron to melt and combine with the silicon. The following chemical reactions occur:

- SiO2 (silica) + 2C (carbon) → Si (silicon) + 2CO (carbon monoxide)

- Fe (iron) + Si (silicon) → FeSi (ferrosilicon)

The carbon monoxide (CO) produced is typically vented or captured for other industrial processes.

4. **Alloy Formation:** As the silicon and iron combine, they form ferrosilicon, which is a solid alloy. The exact composition and grade of ferrosilicon are controlled by adjusting the proportions of the raw materials and the furnace conditions.

5. **Casting:** Once the ferrosilicon alloy has formed, it is tapped or poured from the electric arc furnace into molds to create specific shapes or sizes, depending on the desired final product. The ferrosilicon is cast into various forms, such as ingots, granules, or crushed into smaller sizes.

6. **Cooling and Solidification:** The cast ferrosilicon cools and solidifies in the molds. The cooling rate can affect the microstructure and properties of the final product.

7. **Crushing and Sizing:** After solidification, the ferrosilicon is often crushed into the desired particle size or form. Different grades and particle sizes of ferrosilicon are produced to meet various industrial requirements.

8. **Packaging and Shipping:** The finished ferrosilicon products are packaged for shipment to customers. They may be stored in bulk or in bags, depending on the customer's needs.

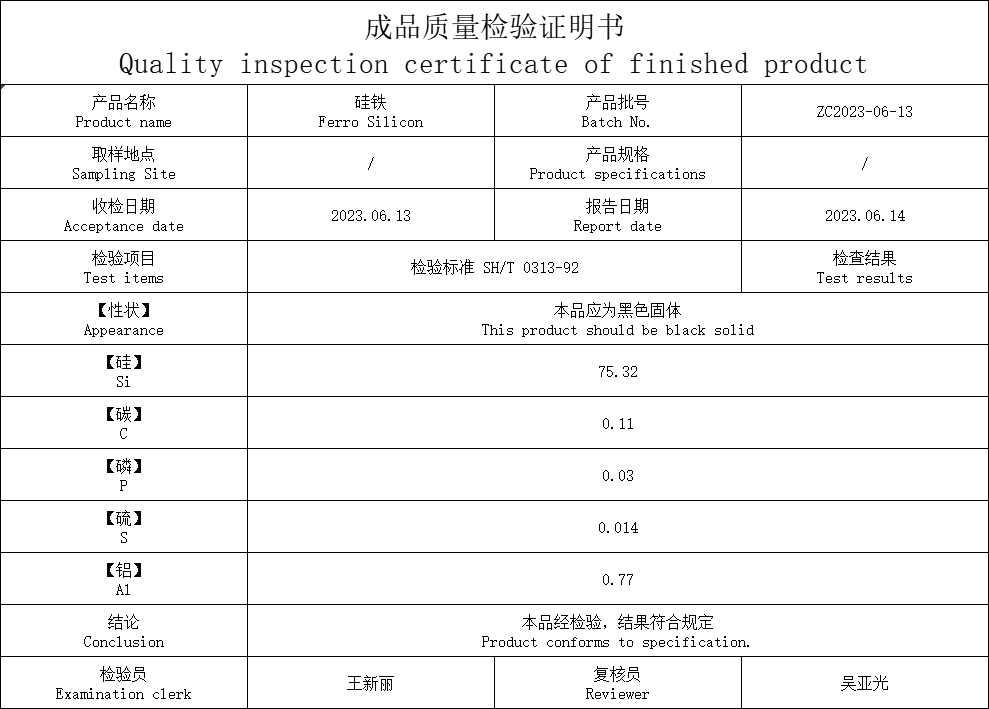

9. **Quality Control:** Throughout the production process, quality control measures are in place to ensure that the final product meets the specified chemical composition and physical properties required by customers.

Ferrosilicon production is a complex and energy-intensive process, but it is crucial for various industrial applications, particularly in the steel and foundry industries. The specific details of the process may vary depending on the equipment and technology used by different manufacturers and the desired grade of ferrosilicon.