Effect Of Graphitized Petroleum Coke On Smelting

Using graphitized petroleum coke (GPC) in foundries offers several benefits. Here are some key advantages:

Carbon Additive: GPC serves as a carbon additive in foundry applications. It helps increase the carbon content in the molding sand mixture or as a separate material, enhancing the carbon content in the metal during casting. This promotes improved casting quality and performance.

Graphite Formation: GPC contains a highly graphitic structure, which promotes the formation of graphite during solidification. The presence of graphite provides lubrication, improves mold release, enhances the machinability of castings, and reduces the likelihood of defects such as shrinkage and porosity.

Nucleating Agent: GPC acts as a nucleating agent, facilitating the formation of graphite flakes in the molten metal. This controlled graphite formation influences the solidification process, promoting the desired microstructure and improving the mechanical properties of the castings, such as strength, toughness, and wear resistance.

Thermal Properties: GPC possesses good thermal conductivity, which aids in heat transfer during the casting process. It helps distribute heat more evenly within the mold, ensuring efficient solidification and minimizing thermal gradients. This results in reduced casting defects and improved dimensional accuracy.

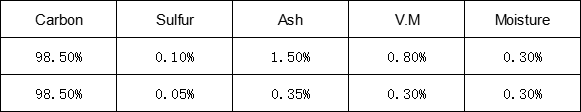

Low Impurity Content: GPC is processed to have low impurity levels, including sulfur, nitrogen, and volatile matter. The low impurity content helps minimize the formation of unwanted by-products and reduce the risk of casting defects or metallurgical issues. It contributes to the overall quality and purity of the castings.

Consistent Quality: GPC production processes are well-established, ensuring consistent quality from batch to batch. Manufacturers can rely on the consistent properties of GPC to achieve uniform carbon content and reliable performance in foundry applications. This helps maintain process control and reduces variability in the casting production.

Cost-Effectiveness: GPC is a cost-effective carbon additive compared to alternative carbon sources. Its availability, efficient production process, and desirable properties make it a favorable choice for many foundries. GPC offers a balance of cost and performance, contributing to cost optimization in casting processes.

In summary, using graphitized petroleum coke in foundries provides benefits such as enhanced carbon content, graphite formation, nucleation promotion, improved thermal properties, low impurity content, consistent quality, and cost-effectiveness. These advantages contribute to improved casting quality, enhanced process control, reduced defects, and increased efficiency in foundry operations.

Graphitized petroleum coke(GPC) Role in foundry factory

Graphitized petroleum coke plays a significant role in foundry factories, particularly in the production of cast iron and steel. Here are some key roles of graphitized petroleum coke in foundry applications:

Carbon Additive: Graphitized petroleum coke is commonly used as a carbon additive in foundry applications. It is added to the molten metal to adjust the carbon content and improve the final properties of the castings. Carbon acts as a reducing agent, facilitating the removal of impurities and ensuring proper alloying of the molten metal.

Increasing Carbon Content: Graphitized petroleum coke, due to its high carbon content, helps increase the carbon content of the molten metal. This is especially important in steelmaking, as the carbon content influences the hardness, strength, and other mechanical properties of the final product. By adding graphitized petroleum coke, the desired carbon levels can be achieved, enabling the production of castings with specific characteristics.

Improving Melt Quality: The addition of graphitized petroleum coke to the melt helps refine the grain structure and improve the overall quality of the metal. It promotes the formation of fine-grained structures, reducing the risk of defects like porosity and enhancing the mechanical properties of the castings. Additionally, graphitized petroleum coke assists in reducing the sulfur content in the melt, minimizing the formation of harmful sulfides.

Enhancing Thermal Conductivity: Graphitized petroleum coke possesses high thermal conductivity, making it an ideal additive in foundry applications. By incorporating it into the melt, the thermal conductivity of the metal is improved, facilitating efficient heat transfer during the solidification process. This promotes uniform cooling and solidification, reducing the likelihood of casting defects like shrinkage and ensuring consistent casting quality.

Controlling Melting and Pouring Temperatures: The addition of graphitized petroleum coke in the foundry process helps control the melting and pouring temperatures of the metal. It assists in maintaining the desired temperature range for optimal casting quality and facilitates the proper flow of molten metal during casting operations.

Overall, graphitized petroleum coke serves as a carbon additive in foundry factories, contributing to the control of carbon content, improving melt quality, enhancing thermal conductivity, and enabling the production of high-quality castings with desirable mechanical properties.