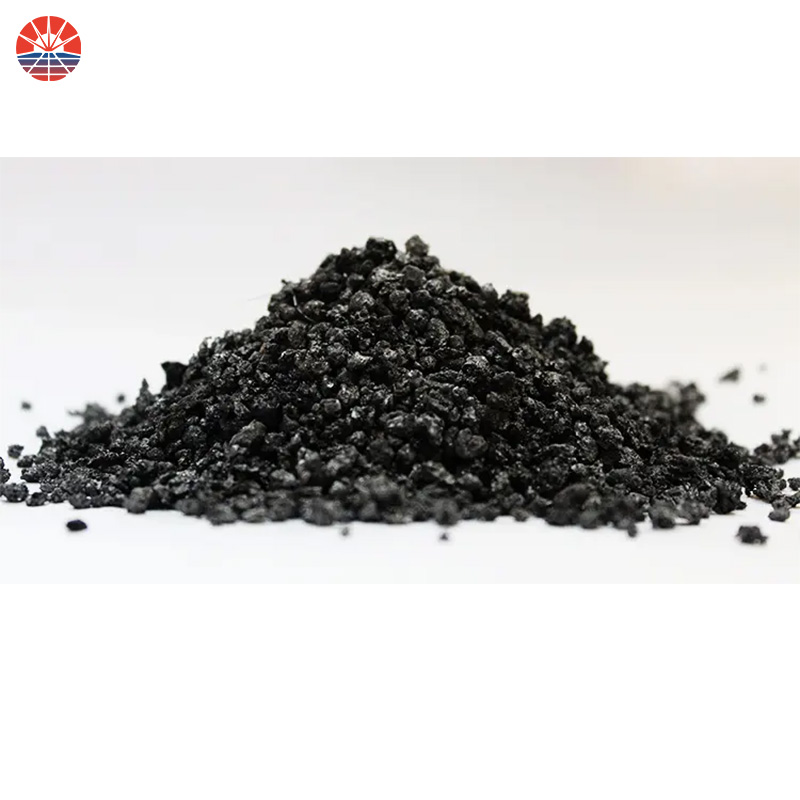

Graphite Petroleum Coke Manufacturer

Using graphitized petroleum coke (GPC) in pre-baked anodes for aluminum production offers several benefits. Here are some of the key advantages:

High Carbon Content: GPC typically has a high carbon content, often exceeding 99%. This high carbon content ensures that the anodes provide a sufficient carbon source during the electrolysis process. It promotes efficient reduction of alumina (Al2O3) to aluminum (Al), leading to increased metal yield and improved energy efficiency.

Superior Electrical Conductivity: GPC possesses excellent electrical conductivity due to its highly graphitic structure. This property allows for efficient transfer of electrical current during the electrolysis process. Anodes made with GPC enable effective electron flow, ensuring optimal energy transfer and reducing energy losses.

Enhanced Thermal Stability: GPC exhibits high thermal stability, allowing it to withstand the extreme temperatures experienced during aluminum electrolysis. The anodes made with GPC maintain their structural integrity and resist degradation, even under the intense heat generated in the electrolytic cell. This ensures longer anode life and reduces downtime for anode replacement.

Low Volatile Matter: GPC is processed to have a low volatile matter content, reducing the emissions and potential for anode cracking or breakage during the baking process. Low volatile matter also helps minimize the formation of unwanted by-products and improve the overall purity of the aluminum produced.

Controlled Ash Content: GPC is produced with a controlled ash content, ensuring that the anodes have minimal impurities. This helps maintain the purity of the aluminum produced, reducing the risk of contamination or unwanted reactions in the electrolytic cell.

Improved Anode Performance: The combination of high carbon content, superior electrical conductivity, and thermal stability in GPC contributes to improved anode performance. Anodes made with GPC exhibit better current efficiency, reduced voltage drop, and enhanced dimensional stability. These factors result in more efficient aluminum production, reduced energy consumption, and improved overall process economics.

Consistency and Availability: GPC production processes are well-established, allowing for consistent quality and availability of the material. Manufacturers can rely on the consistent properties of GPC to produce high-quality anodes, ensuring consistent performance and reducing variability in the aluminum production process.

In summary, using graphitized petroleum coke in pre-baked anodes provides benefits such as high carbon content, excellent electrical conductivity, thermal stability, low volatile matter, controlled ash content, improved anode performance, and consistent quality. These advantages contribute to more efficient and sustainable aluminum production, enhancing process economics and product quality.

Graphitized petroleum coke Role in prebaked anode

Graphitized petroleum coke plays a crucial role in the production of prebaked anodes for the aluminum industry. Prebaked anodes are a key component in the electrolytic process of aluminum production, specifically in the Hall-Héroult process.

The main functions of graphitized petroleum coke in prebaked anodes are as follows:

Carbon Source: Graphitized petroleum coke provides the primary source of carbon in the anode. Carbon is required to react with alumina (Al2O3) in the electrolytic cell to produce aluminum through the electrochemical reduction process. The high carbon content in graphitized petroleum coke ensures a sufficient supply of carbon during the aluminum production process.

Electrical Conductivity: Graphitized petroleum coke possesses excellent electrical conductivity due to its highly ordered graphite structure. This property is crucial for anodes, as they need to conduct electricity effectively in the electrolytic cell. The high electrical conductivity of graphitized petroleum coke allows for efficient electron transfer during the electrolysis process, facilitating the production of aluminum.

Thermal Stability: Prebaked anodes are subjected to extreme conditions of temperature and chemical reactions during the aluminum smelting process. Graphitized petroleum coke exhibits high thermal stability, which enables it to withstand the intense heat and chemical environments inside the electrolytic cell. It helps to prevent anode degradation, maintain structural integrity, and ensure the longevity of the anode.

Low Impurity Content: Graphitized petroleum coke is processed to remove impurities, such as volatile matter, sulfur, and metals, during the calcination and graphitization stages. The low impurity content is essential to prevent unwanted reactions and contamination in the electrolytic cell. It also helps to maintain the purity of the aluminum produced.

Overall, graphitized petroleum coke serves as a high-quality carbon material that provides the necessary carbon source, electrical conductivity, thermal stability, and low impurity content required for efficient and sustainable aluminum production through the prebaked anode process.