Graphited Petroleum Coke in Casting Plant

High Carbon Content:The carbon content is usually above 98%, which makes it a desirable material for carbon and graphite production.

Low Impurities:Low levels of impurities such as sulfur, nitrogen, and volatile matter which are critical, such as in the manufacturing of high-quality graphite electrodes.

Excellent Conductivity

Thermal Stability

Graphitized petroleum coke supplier

As graphited petroleum coke manufacturer,we have successfully diversified into areas that few players have ventured into;graphited petroleum coke business is one such example.

Today, our GPC business is growing with many projects already in hand and the Group’s in-house GPC consultancy firm consolidates its position in this segment.

Specification of graphitized petroleum coke

| Carbon | Sulfur | Ash | V.M | Moisture |

| 98.50% | 0.10% | 1.50% | 0.80% | 0.30% |

| 98.50% | 0.05% | 0.35% | 0.30% | 0.30% |

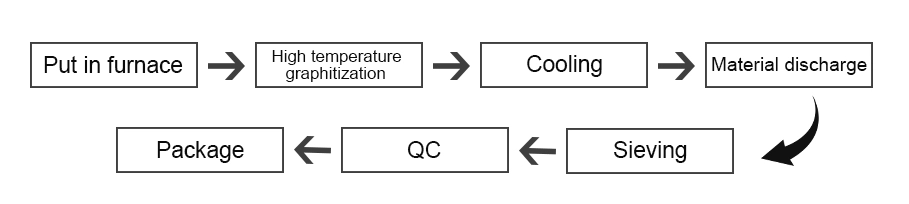

Production line of graphitized petroleum coke

The graphitized petroleum coke (GPC) production line begins with the selection of high-quality raw petroleum coke, followed by a calcination process to remove volatile components. The material is then crushed, sized, and, if necessary, blended to achieve desired properties. The crucial step is graphitization, involving high-temperature heating in the presence of a catalyst to transform carbon into a crystalline structure. After cooling and additional processing for quality enhancement, the final GPC product undergoes rigorous quality control