What Are The Properties Of Graphitized Petroleum Coke

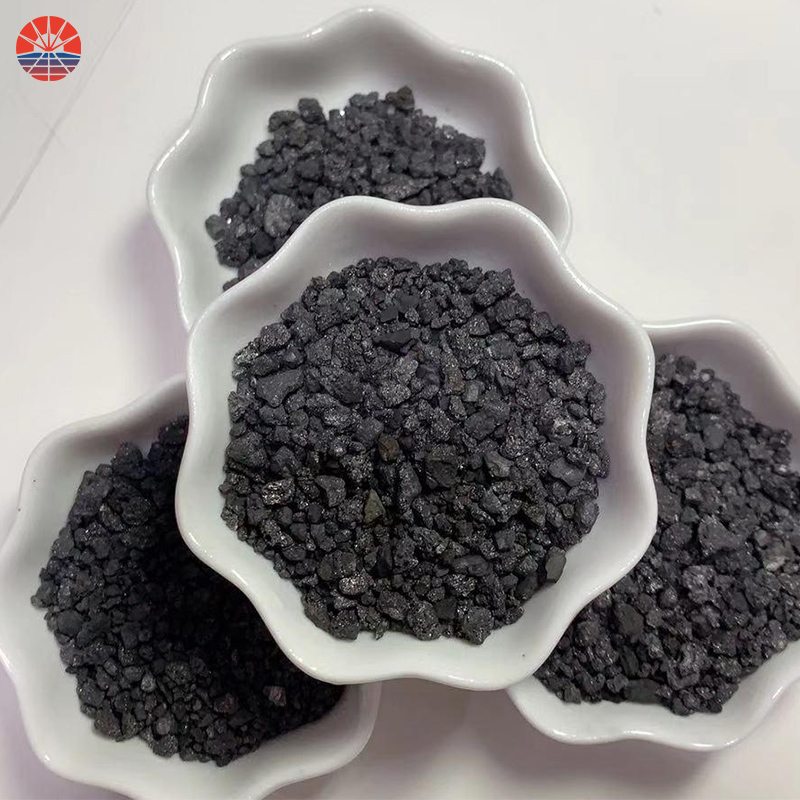

Graphitized Petroleum Coke (GPC) is a carbonaceous material with unique properties ideal for various industrial applications:

1. High Carbon Content: GPC typically contains over 98% carbon, making it a valuable carbon source in metallurgy.

2. Electrical Conductivity: GPC is an excellent conductor of electricity, essential in aluminum smelting and electric arc furnaces.

3. Thermal Conductivity: GPC's high thermal conductivity ensures even heat distribution in industrial processes.

4. Graphitic Structure: Through graphitization, GPC transforms into a crystalline graphite structure, enhancing its electrical and thermal properties.

5. Low Impurities: High-quality GPC has minimal impurities, reducing the risk of contamination in industrial processes.

6. Low Sulfur and Nitrogen: Low sulfur and nitrogen content in GPC makes it suitable for applications demanding purity.

7. Hardness: GPC exhibits hardness and durability, crucial for abrasives and refractories.

8. Cost-Effectiveness: GPC is a cost-efficient alternative to synthetic graphite, contributing to cost savings.

9. Environmental Impact: Efficient GPC utilization can lower energy consumption and emissions, aligning with environmental regulations.

10. Versatility: GPC's versatility extends to steel production, foundries, and brake linings, among other industrial applications.

What Are The Properties Of Graphitized Petroleum Coke

Graphitized Petroleum Coke (GPC) is a specialized form of petroleum coke that undergoes a heat treatment process called graphitization. This process transforms the amorphous carbon in petroleum coke into a crystalline graphite structure. GPC has several distinct properties, which make it suitable for various industrial applications:

1. **High Carbon Content:** GPC typically contains a carbon content of over 98%, making it an excellent carbon source in metallurgical processes.

2. **Electrical Conductivity:** GPC exhibits high electrical conductivity, making it valuable in applications like aluminum smelting, where it serves as an anode material.

3. **Thermal Conductivity:** GPC has good thermal conductivity, ensuring even heat distribution in industrial processes.

4. **Graphitic Structure:** The graphitization process imparts a highly ordered, crystalline graphite structure to GPC, enhancing its electrical and thermal properties.

5. **Low Impurities:** High-quality GPC has minimal impurities, which is crucial for applications where purity is essential to prevent contamination.

6. **Low Sulfur and Nitrogen:** GPC typically contains low levels of sulfur and nitrogen, making it suitable for applications demanding low impurity levels.

7. **Hardness:** GPC exhibits hardness and durability, making it valuable in applications like abrasives and refractories.

8. **Cost-Effectiveness:** GPC is often a cost-effective alternative to synthetic graphite, contributing to cost savings in various industries.

9. **Environmental Impact:** Efficient utilization of GPC can lead to reduced energy consumption and emissions, aligning with environmental regulations.

10. **Versatility:** GPC's versatility extends to applications beyond aluminum smelting, including steel production, foundries, brake linings, and more.

These properties make graphitized petroleum coke a valuable material in industries where high-purity carbon with excellent electrical and thermal conductivity is required. Its ability to enhance the performance of various industrial processes, coupled with its cost-effectiveness, makes it a preferred choice for many applications.